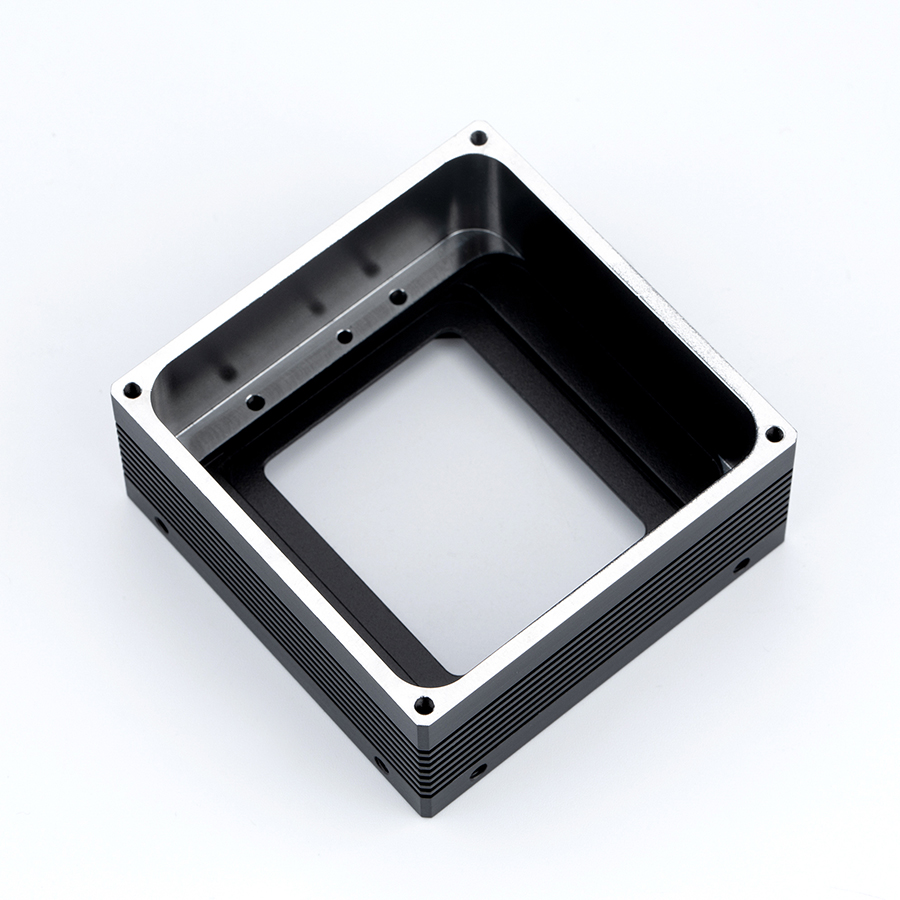

Factory Black Oxidation CNC Aluminium Milling Precision Parts CNC Machining Parts

cnc machining ke eng?

CNC e ka sebelisoa ho hlahisa likarolo tsa machining le li-prototypes ka potlako haholo ka ho nepahala ho phahameng, ka tekanyo e phahameng ea tlhahiso, thepa e sebelisoang e matla ebile e tšoarella bakeng sa tlhahlobo.

CNC machining ke ts'ebetso ea tlhahiso ea ho ntša e sebelisang lisebelisoa tse bilikang tse laoloang ke komporo joalo ka li-drill, li-mill tsa ho qetela, le lisebelisoa tse fetolang ho tlosa thepa ho tsoa ho block e tiileng ea thepa, ka hona ho bopa karolo.

Lifaele tsa mananeo a dijithale li tsamaisa mechine ea CNC mokhoa oa ho khaola thibela (e tsejoang hape e le "workpiece") le mechine e mengata e ka sebelisa faele e tšoanang ea lenaneo ka nako e le 'ngoe, e leng ho eketsang haholo lebelo la tlhahiso ea tlhahiso.

CNC machining ke khetho e sebetsang bakeng sa ho etsa likarolo tse nang le mefuta e mengata ea lisebelisoa le lisebelisoa tse holimo.Senze Precision e fana ka mefuta e mengata e felletseng ea lits'ebetso tsa ho sila tsa CNC, ho cheka, ho bora, ho qoelisoa, ho koenya, ho tlanya, ho tsosolosa, terata EDM le EDM, le tse ling.Re ka hlahisa likarolo tsa hau tsa mochini oa CNC ka potlako tse nang le mamello e thata le thepa e ntle haholo ea mochini.

melemo ea ho sebetsa ka cnc

1.Boleng bo botle, ho nepahala ho phahameng le tlhahiso e phahameng.

Ts'ebeletso ea mochini oa 2.CNC e ka hlahisa likarolo tse nang le meaho e rarahaneng.

3.Tsehetsa lisebelisoa tse sa tšoaneng, ho kenyelletsa le mefuta eohle ea lisebelisoa tsa tšepe: aluminium, tšepe, koporo, tšepe e sa hloekang, alloy ea titanium le polasetiki.

4.Molumo o monyenyane o tla ba bonolo ebile o potlakile bakeng sa tlhahiso, mme o molemo ho laola boleng le ho boloka litšenyehelo.

5. Ha e hloke ho bula hlobo, likaroloana tse nyenyane li ke ke tsa ba le tefiso e phahameng ea hlobo.

Khamphani ea Senze e ikhethang ka nepo e phahameng ea 3 4 5 axis CNC Machining likarolo tse entsoeng ka letsoho OEM e nang le theknoloji ea maemo a holimo.

CNC machining e kenyelletsa tekheniki ea ho fetola le ho sila.

Milling

1. Sekwere sa mochini, khutlonnetsepa, chitja + khutlonnetsepa.

2. E sebelisetsoa ho sebetsana le lifofane, litepisi, li-grooves, meno a li-gear, likhoele, li-spline shafts, ho etsa libaka le ho khaola li-workpieces, hape li sebetsana le litlaleho tse rarahaneng joalo-joalo ...

3. Ho sebetsa hantle haholo, ho nepahala ho phahameng.

4. E sebelisoa haholo mafapheng a ho etsa le ho lokisa mechine.

Lathe/ Ho fetola

1. Ho sebetsa likarolo tse chitja.

2. Haholo-holo e sebelisa sesebelisoa sa ho fetola ho fetola mosebetsi o potolohang.

3. E sebelisoa bakeng sa liboro, li-reamer, li-reamers, lipompo, lisebelisoa tsa dies le tsa knurling

4. Lebelo le phahameng, ho nepahala ho phahameng

Re hantle ho

1.5/4/3 axis CNC machining

2.CNC ho fetola mechine.

3.Injection molding, Die cast cast

4.Sheet metal fabrication, tšebeletso ea ho itšeha laser.

5.Kalafo ea holim'a metsi

6.QC tsamaiso ea teko: VMS / CMM QC tlhahlobo

7.Certification Re na le:ISO9001:2015

Lisebelisoa tsa cnc machining

Mokhoa oa ho sebetsa oa cnc machining

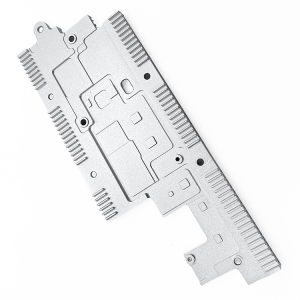

Likarolo tse ling lifoto tsa likarolo tsa machining tsa cnc

Boemo ba Khoebo

SENZE CNC Machining OEM Factory

SENZE e sebakeng sa No.104,4 Building,Jufeng Derong Industrial Park,Xiaobian Village,ChangAn Town,Dongguan City.OEM CNC Machining le mofani oa khatiso oa 3D.Bareki ba rona ba koahelaEurope le Amerika.SENZE e khethehileng ka ho nepahala ho phahameng 3/4/5 axis CNC likarolo tse sebetsang tse hlahisang ka theknoloji e phahameng.

Lisebelisoa tsa likarolo tsa machining tsa cnc

1.Advance CNC lathes setsi sa machining

2.DMG 5 axis CNC setsi sa machining

3. 3/4 axis CNC setsi sa machining

Mechine ea 4.EDM/WEDM

5.Mold--plastics / tšepe hlobo setsi sa tšebeletso

6.VMS + CMM QC tsamaiso ea teko.

Basebetsi ba nang le tsebo bakeng sa likarolo tsa machining tsa cnc

5 axis CNC machining workshop

4 axis CNC machining workshop

Sistimi ea Taolo ea Boleng e tiileng

SENZE e na le ts'ebetso e tiileng ea taolo ea boleng, hape e rekisitse CMM(Coordinate Measuring Machine), le VMS(Projector) e le ho fihlela maemo a boleng ba bareki.Bareki ba rona ba ts'epa hore re tla fana ka eona lekhetlo la pele mme ba ka itšetleha ka sehlopha sa rona sa baenjiniere ba nang le boiphihlelo le ho fana ka thepa ka nako.

Likarolo tsa ho sebetsa tsa CNC