CNC Machining - China Factory, Suppliers, Manufacturers

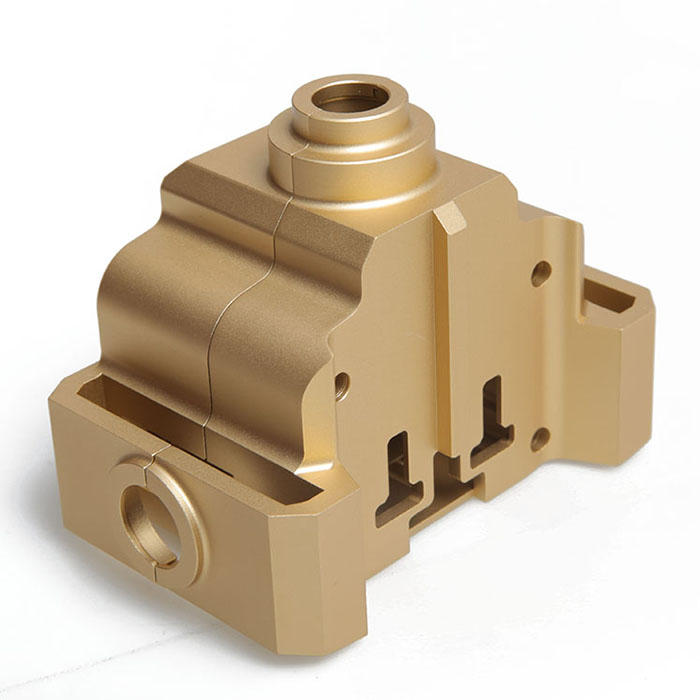

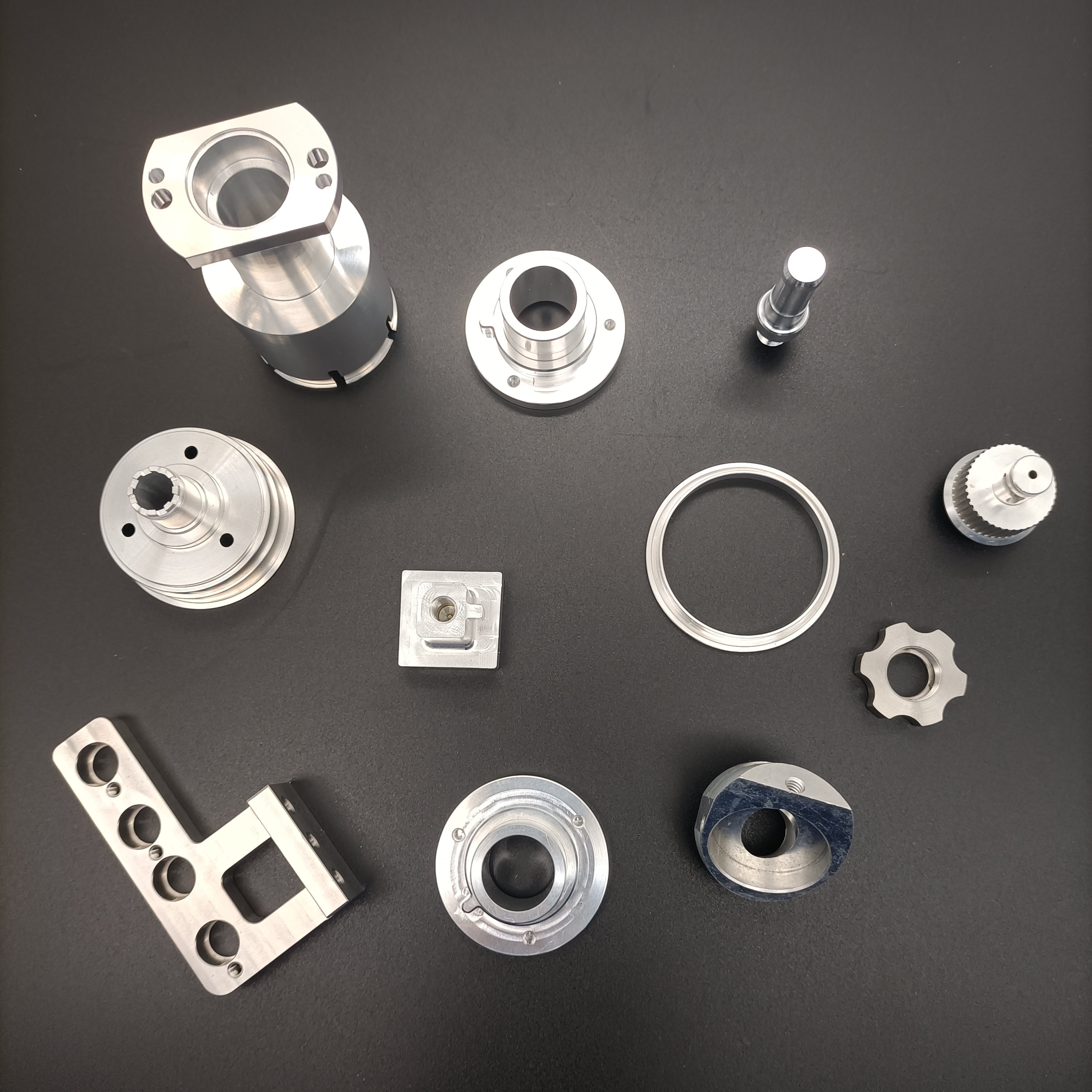

Re lula le molao-motheo oa "boleng ba pele, lits'ebeletso pele, ntlafatso e tsitsitseng le boqapi ba ho phethahatsa bareki" bakeng sa botsamaisi ba hau le "sekoli se se nang letho, litletlebo tse se nang letho" joalo ka sepheo sa boleng.Ho phethahatsa k'hamphani ea rona, re fana ka thepa ha re ntse re sebelisa boleng bo holimo ka theko e ntle ea ho rekisa bakeng sa CNC Machining,Likarolo tsa Axis tsa Cnc 5 , Custom Milling Machining Parts , Aerospace Machining likarolo ,Oxidation Cnc Machining likarolo.Re amohela ka tieo metsoalle ho buisana ka khoebo le ho qala tšebelisano-'moho le rona.Re tšepa ho kopanya matsoho le metsoalle liindastering tse fapaneng ho theha bokamoso bo botle.Sehlahisoa se tla fana ka lefats'e ka bophara, joalo ka Europe, Amerika, Australia, Kuwait, Croatia, Egepeta, Brunei.Lihlahisoa tsa rona li rometsoe haholo ka boroa-bochabela ho Asia Euro-Amerika, le thekiso ho naha eohle ea rona.Mme ho ipapisitse le boleng bo botle, theko e tlase, tshebeletso e ntle ka ho fetisisa, re na le maikutlo a matle ho tswa ho bareki ba mose ho mawatle.O amohelehile ho ikopanya le rona bakeng sa menyetla le melemo e meng.Re amohela bareki, mekhatlo ea likhoebo le metsoalle ho tsoa likarolong tsohle tsa lefats'e ho ikopanya le rona le ho batla tšebelisano-'moho molemong oa bobeli.

Lihlahisoa tse Amanang